The powerful E.KO IONISER® produces first-class process water with an ideal pH value and lowest conductivity.

Its enormously high flow rate enables a fast water supply to your EDM machine.

Ion exchange with the E.KO IONISER®

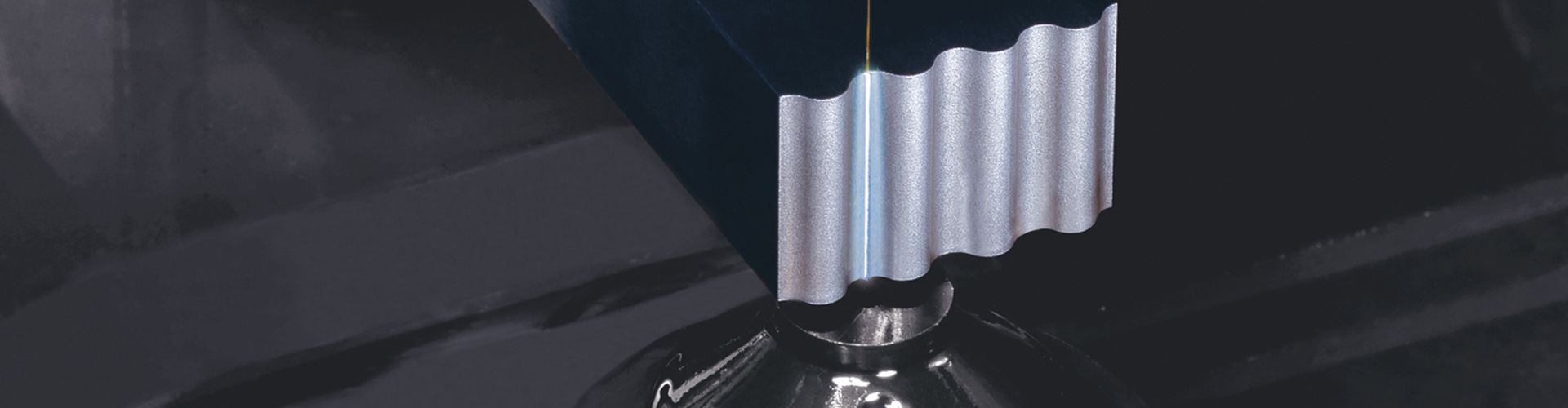

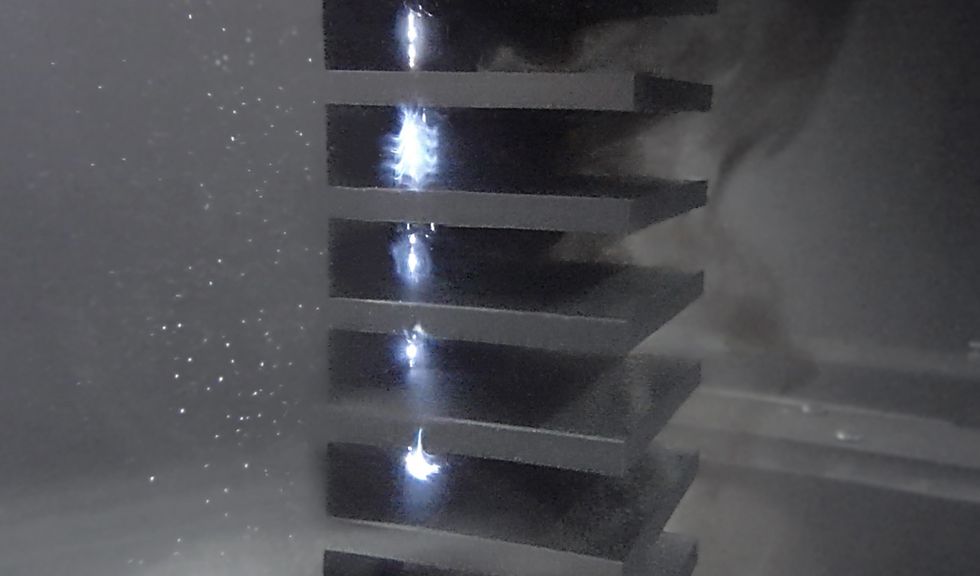

Most precise cutting results.

Protection against corrosion and sedimentation.

Guarantees a long, trouble-free service life.

Reduces the addition of additives to a minimum.

E.KO IONISER® 1501 or E.KO IONISER® 1502

Best surface finish on workpieces.

Excellent workpiece reproducibility.

Minimal corrosion tendency on workpiece and machine. Even if the workpieces remain in the dielectric for a longer period of time.

Consistent product quality and reduction of rejects.

CONNECT4 connection kit

Plug & play EASY quick couplings.

Compatible with all wire eroding machines.

No additional components necessary.

Exclusively industrial components.

Ideal as basic equipment in combination with KORROSTOP4.0®.

![]()

Precise measuring instrument for conductance of inlet and outlet water

Controlled and documented monitoring of water quality (input and output conductance, capacity, water temperature, flow rate).

Avoidance of rejects through quality display for E.KO IONISER® in % (early planning for exchange unit possible).

Control of external devices possible (e.g., warning light, additional pump, ...).

Suitable for all machine manufacturers (CONNECT 4 connection kit).

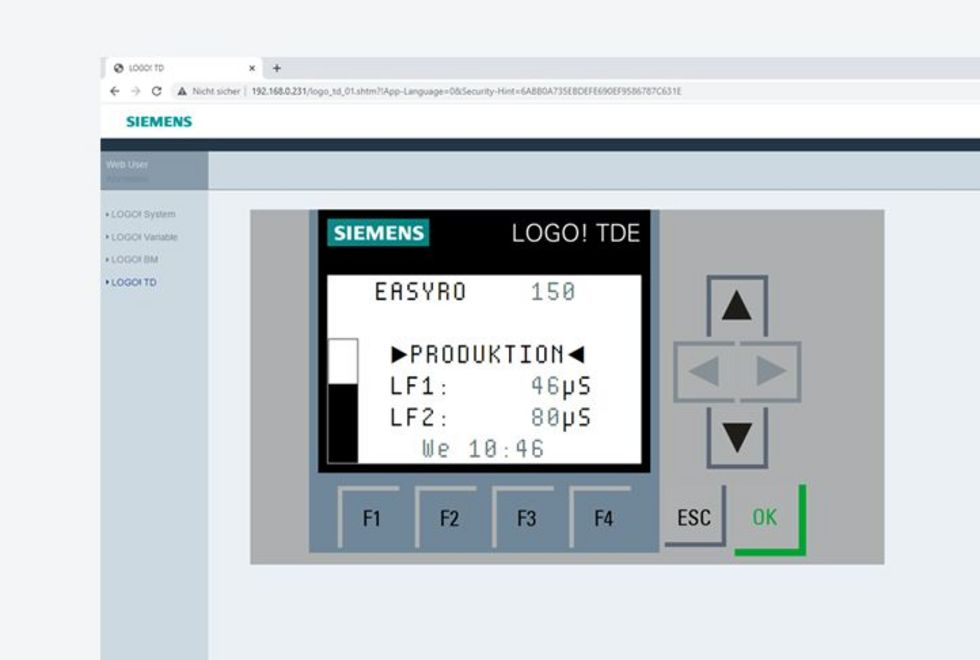

KORROSTOP4.0® on mobile devices

Real-time display of all measured values.

Easy navigation.

Additional information on connection variant and use of a PLC connection.

In conjunction with ioBroker historical data.

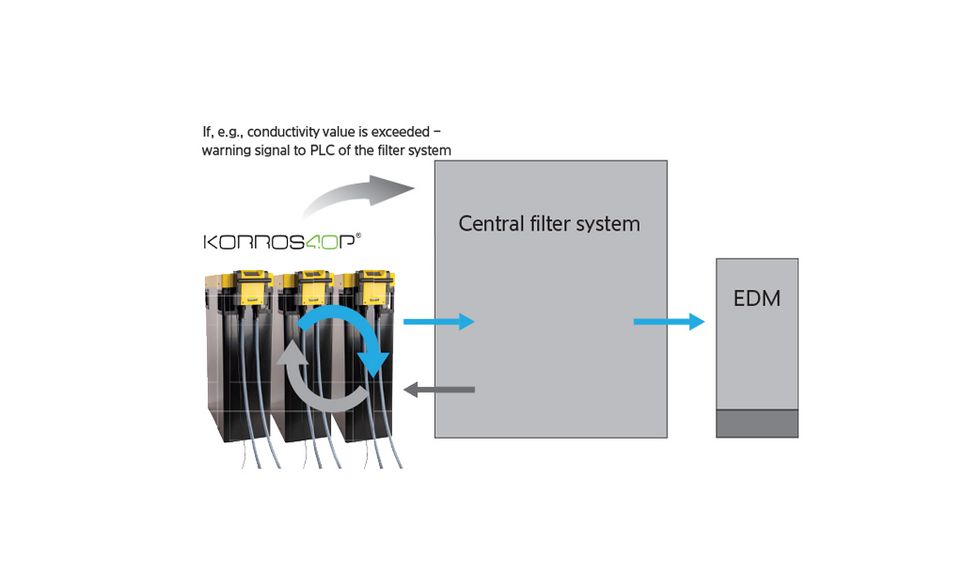

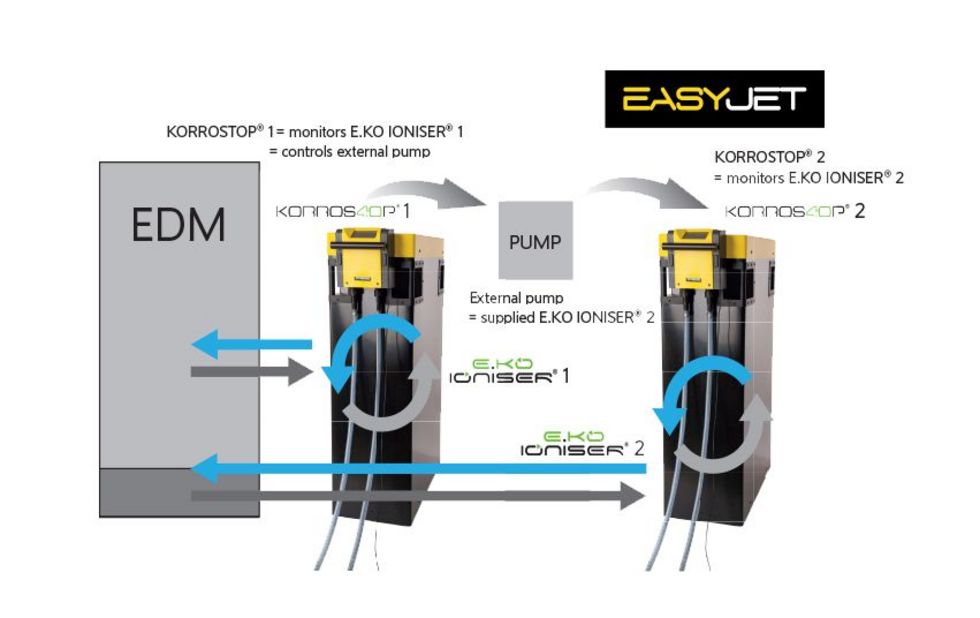

KORROSTOP4.0® connection option

Control of conductance (input and output), quality, temperature and flow.

Control of consumption and service life.

Simple planning for the exchange.

Central control of multiple locations possible.

KORROSTOP4.0® connection option

Control of an external warning system.

Control of an external pump.

2 free configurable switching outputs.

KORROSTOP4.0® connection option

Dealer monitors consumption.

Dealer arranges replacement of the E.KO IONISER® in good time.

Dealer organises logistics.

KORROSTOP4.0® connection option

Control of an additional external pump to increase the flow.

External pump supplies the E.KO IONISER® No. 2.

KORROSTOP4.0® No. 2 monitors the E.KO IONISER® No. 2.

Compact mobility for the E.KO IONISER®.

Steerable wheels with brakes for added safety.

Effortless loading and unloading due to the overall height of a Euro pallet.

Convenient rental concept

Delivered - Docked - Done.

Long, trouble-free service life.

Easy exchange from used to new.

No disposal costs.

The E.KO IONISER® - a recyclable system

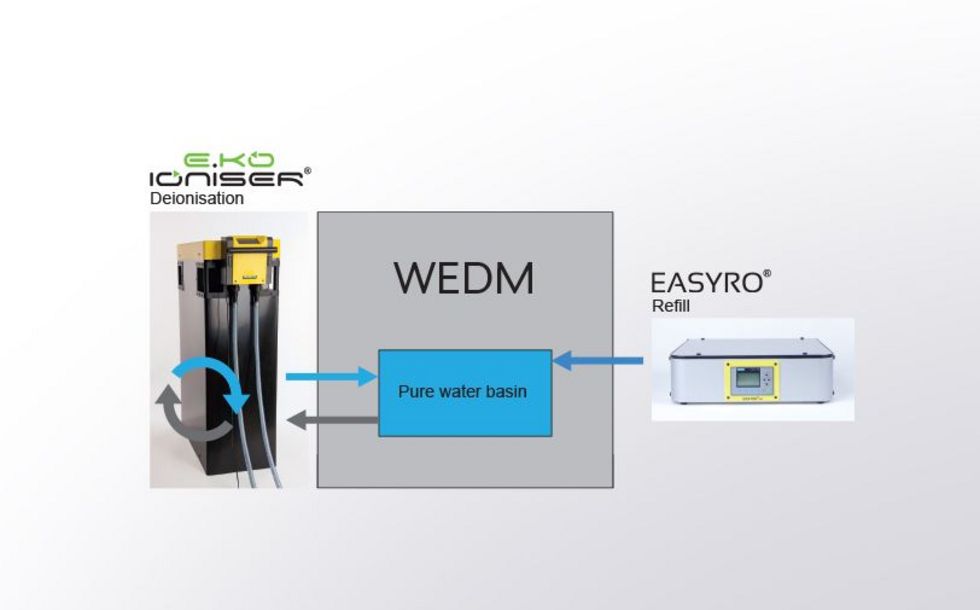

The right water treatment for your refill guarantees a safe cutting process with long running times without annoying interruptions.

With the EASYRO® reverse osmosis system, refilling runs without changing the conductance.

Refilling with the EASYRO® reverse osmosis system

No calcification of the valves.

No premature wire breakage.

No change in conductance during refilling.

Prevents deposits.

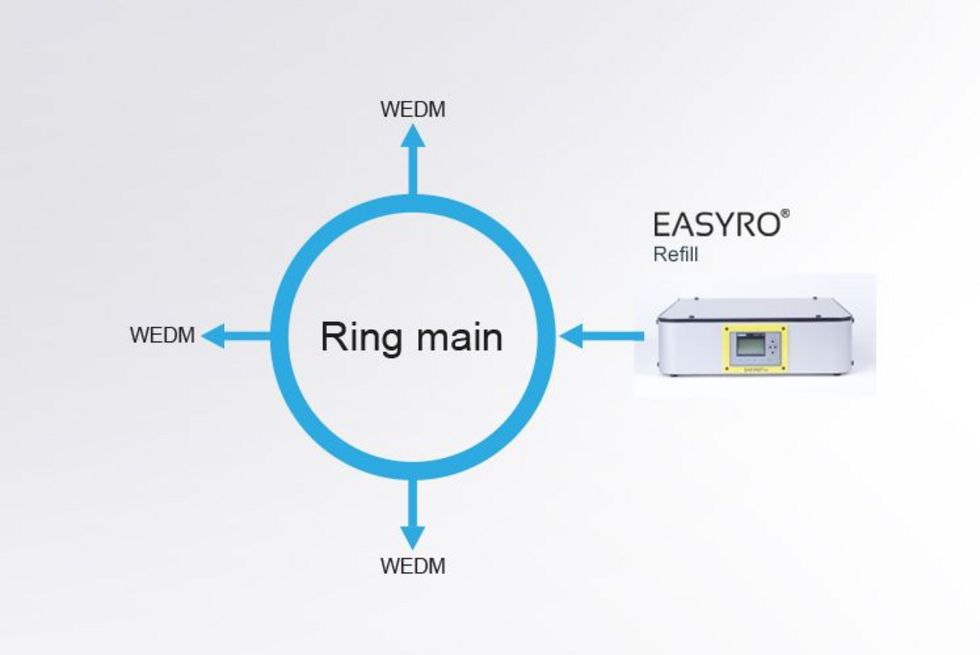

EASYRO® reverse osmosis system

Reliable, cost-effective and environmentally friendly.

Removes 95-99% of molecules, ions and organic impurities from water.

Water quality information on the display.

EASYRO® refill system for your machinery

Use as single or central supply.

With fully automatic refilling - direct feed into the consumer.

Saves time and money.

Modular design - different sizes as required.

Permanent control

Communication in real time.

Information on water quality.

Integrated web server.

Built-in EASYNET interface.