The ideal water for heating and cooling circuits.

Modern heating systems are becoming increasingly sophisticated and require a water quality that meets the standards for the flushing process and filling.

Only the purest water can prevent limescale and damage to the boiler and pipe system.

Purest water through reverse osmosis

Application-specific water qualities.

Removes hardness components (alkaline earth metals), chlorine, ammonium and metal salts.

Removes algae, bacteria and suspended matter.

Prevents deposits and scale.

Significantly decreases Conductance

= soft water (°dh)

EASYRO® reverse osmosis system

Full performance of the systems.

Trouble-free operation of the system.

Prevents corrosion of water and steam-bearing components.

Prevents damage to boilers and pipe systems.

EASYRO® drink+house reverse osmosis system

Variable high-performance membranes.

High desalination rate of 95-99%.

Fully automatic rinse cycles.

Prevents limescale deposits on expensive appliances.

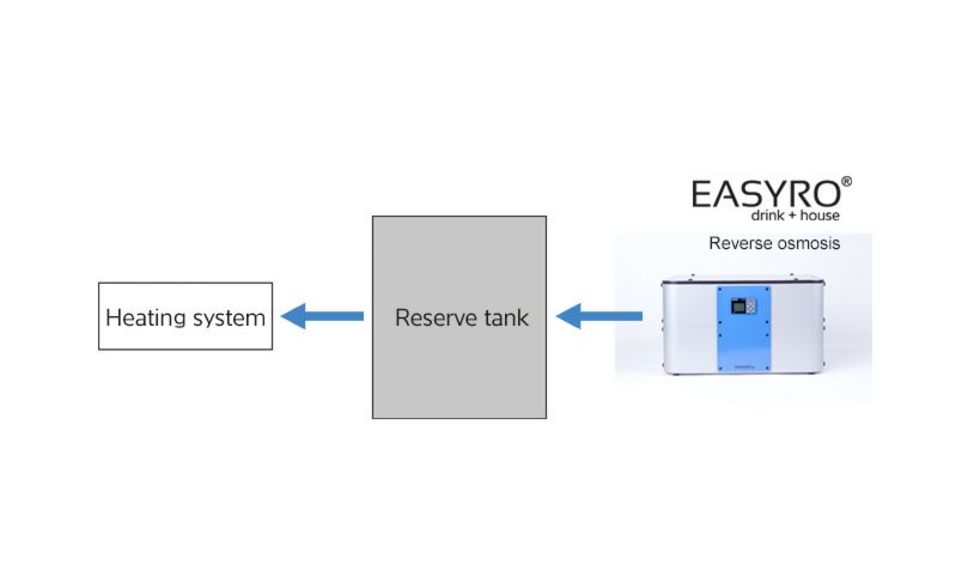

EASYRO® drink+house with different tanks

Different sizes of EASYRO® drink+house.

Pre-filter depending on requirements.

Pressurised and unpressurised tanks available.

Reserve tanks available in different materials and sizes.

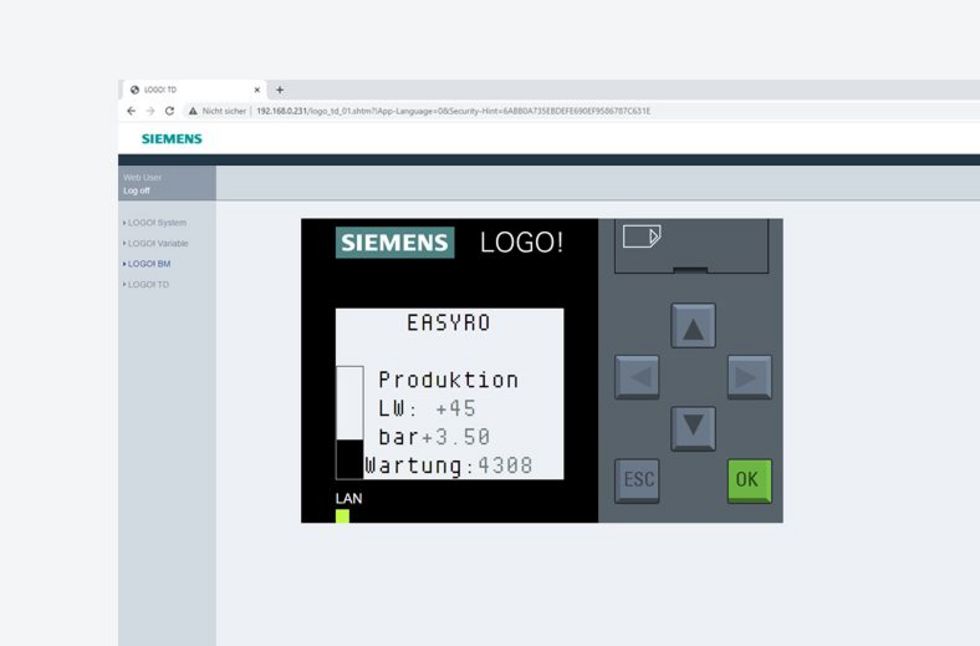

Permanent control

Communication in real time.

Information on water quality.

Integrated web server.

Built-in EASYNET interface.

If conductance of < 1 µS/cm is required, deionisation is the appropriate treatment method.

The E.KO IONISER® 1503 for subsequent smoothing after reverse osmosis guarantees a conductance of 0.055 - 0.1 µS/cm (TREF25).

DI water through ion exchange

Removes all dissolved salts, cations and anions.

Completely removes all hardness components = hardness level 0°dH

Conductivity of up to < 0.1 µs/cm

High dissolving power and high cleaning performance, therefore only recommended in combination with corrosion inhibitors.

E.KO IONISER® 1501/1502/1503 Deionisation (ion exchange)

Removes all ions from water = hardness level 0°dH.

Guaranteed lowest conductance of 0.055 - 0.1 µs/cm.

Resistance of > 18.2 MΩ, TOC value of < 1 ppb.

No investment costs due to rental concept (except accessories).

Full monitoring of water quality in combination with the KORROSTOP4.0®.

![]()

Precise measuring instrument for conductance of inlet and outlet water

Consistent product quality through water quality monitoring.

All measurement data in real time.

Quality display for E.KO IONISER® in % thereby planning for exchange unit possible.

Industry 4.0 - can be fully integrated into existing company IT.

The E.KO IONISER® - a recyclable system