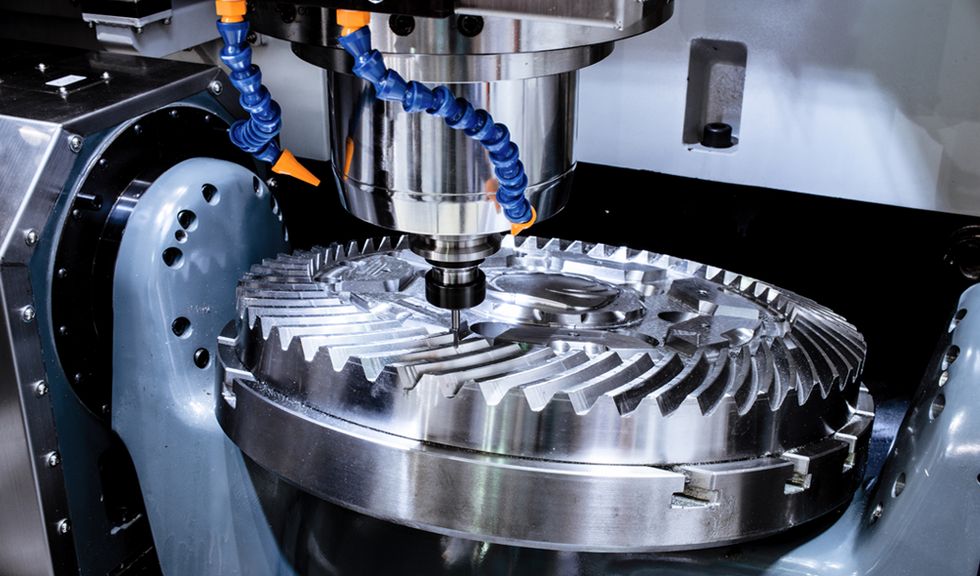

Pure water as a preparation medium not only extends the service life of the emulsion, it also reduces the overall process costs through increased operational reliability.

Purest water through reverse osmosis and ion exchange

Application-specific water qualities (hardness levels).

Stable, consistent water quality

Bacterial stability (no organic contamination) - no bacterial contamination from refilling.

Guarantees long, trouble-free service life of the cooling lubricants.

Guarantees more efficient work processes.

EASYRO® reverse osmosis system

Reduces staining on the workpiece and residues on the machine.

Reduces corrosion or residues on the machine.

No hardness (hardening soaps), no metal salts, no turbidity.

No chlorides, sulphates, nitrites, nitrates.

Removes suspended solids, smallest molecules and organic impurities almost completely.

Pure water with a low conductance

EASYRO® reverse osmosis system

Variable high-performance membranes.

High desalination rate of 95-99%.

Fully automatic rinse cycles.

2 separate outlets for different water qualities.

Output 1 - conductance adjustable

Output 2 - conductance fixed

Pure water for increased operational safety

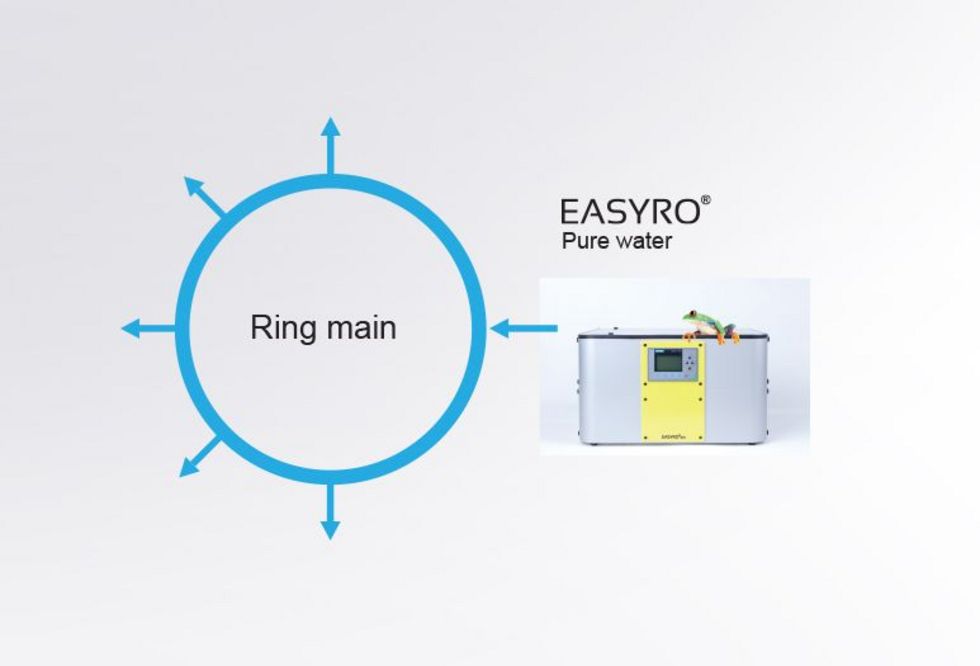

Use as single or central supply.

With fully automatic refilling - direct feed into the consumer.

Modular design - different sizes as required.

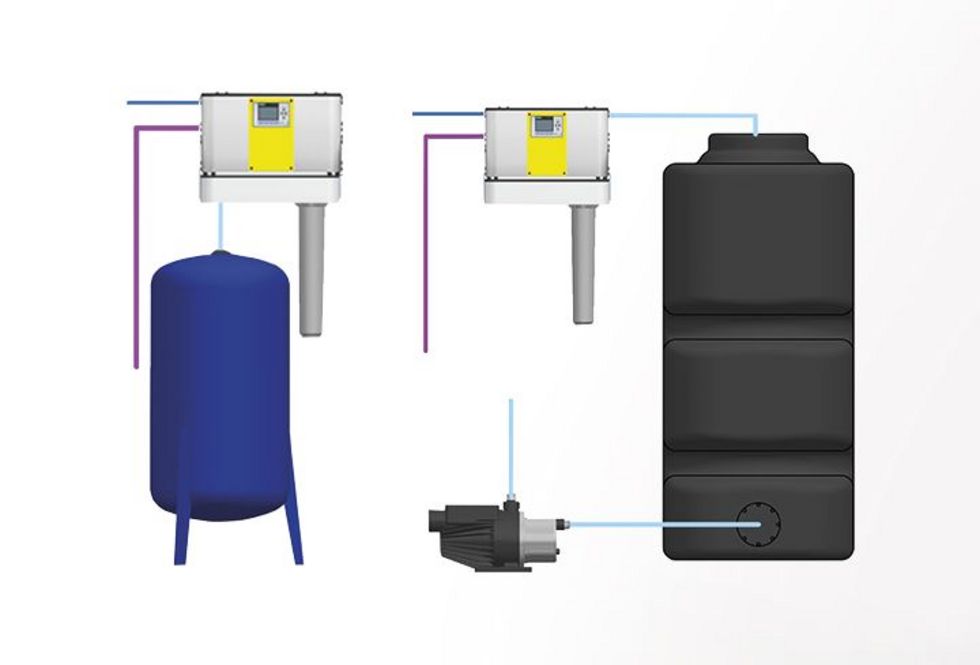

Also available with a pressurised tank or an unpressurised tank.

Water reserve depending on requirements

Pressurised or unpressurised tank systems (with external pump) selectable.

Can be equipped with UVC lamp system (unpressurised tank systems only).

Unpressurised tanks can be used as a basic or additional tank.

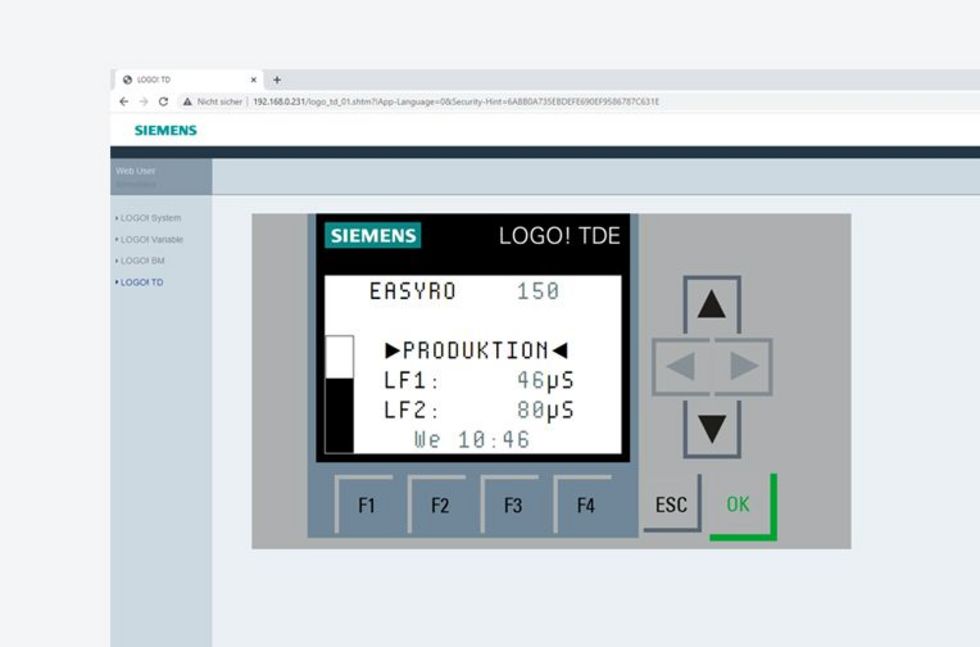

Permanent control

Communication in real time.

Information on water quality.

Integrated web server.

Built-in EASYNET interface.

Due to the heating and evaporation process, the emulsion accumulates the salts remaining in the cooling circuit and leads to an undesired salinisation.

Faster evaporation of the water means greater increases in salts.

E.KO IONISER® deionisation (ion exchange)

No salinisation as with cation exchangers (salt content approximately as high as fresh water).

Lowest conductance, removes all dissolved cations and anions.

No residues or corrosion on workpiece and machine.

Removal of Total Organic Carbon (TOC) of < 1 ppb.

Constant neutral pH value (additional removal of carbonic acid and silicic acid).

E.KO IONISER® 1501/1502/1503 Deionisation (ion exchange)

Removes all ions from water = hardness level 0°dH.

Guaranteed lowest conductance of 0.055 - 0.1 µs/cm.

Resistance of > 18.2 MΩ, TOC value of < 1 ppb.

No investment costs due to rental concept (except accessories).

Full monitoring of water quality in combination with the KORROSTOP4.0®.

![]()

Precise measuring instrument for conductance of inlet and outlet water

Consistent product quality through water quality monitoring.

All measurement data in real time.

Suitable for all machine manufacturers (CONNECT 4 connection kit).

Compact mobility for the E.KO IONISER®.

Steerable wheels with brakes for added safety.

Effortless loading and unloading due to the overall height of a Euro pallet.

Convenient rental concept

Delivered - Docked - Done.

Long, trouble-free service life.

Easy exchange from used to new.

No disposal costs.

The E.KO IONISER® - a recyclable system