Whether for production purposes or for drinking water treatment, special solutions in water treatment are needed in many areas of application.

When realising special solutions, we rely on innovative and flexible concepts with state-of-the-art technologies.

We support you from project planning to commissioning and maintenance of the systems.

With over 20 years of experience in water treatment, we have the necessary expertise to successfully realise your project together with you.

Here is a small excerpt of our special solutions.

Golf course with bistro and restaurant

Requirement:

Supply of the entire golf course incl. bistro and restaurant with fresh drinking water, service water and industrial water.

No use of local water possible. Water treatment of a well contaminated by agricultural use.

Solution:

Supply of the entire golf course with fresh drinking water, service and industrial water at 7°dH (Austrian drinking water standard).

Feeding the kitchen, coffee machines and dishwashers of the bistro and restaurant with drinking water at 0°dH.

Installation of a water treatment system based on reverse osmosis with coordinated pre-filter stages including a certified UVC system. Additional activated carbon filters and blending to 7°dH.

Performance: 72,000 litres/day

EDM - work tank in Electrical Discharge Machining

Requirement:

When eroding hard metal, special materials (e.g., molybdenum) or thin-wire applications, the conductance in the machine basins increases very quickly. This negatively affects the erosion process.

Customer requirement: Conductance of 1 µs/cm and increase of flow rate

Solution:

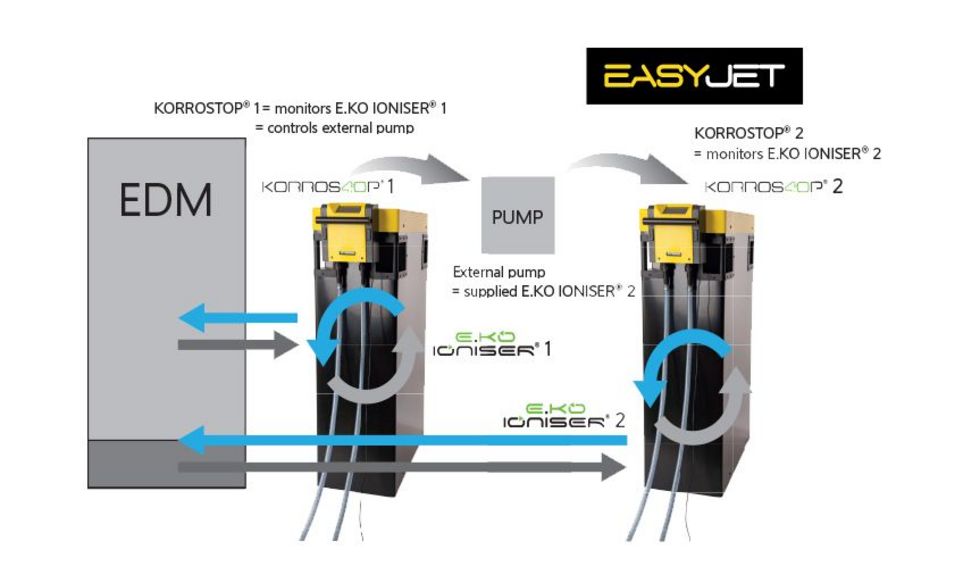

Equipment: 2 x E.KO IONISER® each with a KORROSTOP4.0® and an external pump

Principle: KORROSTOP4.0® 1 controls external pump - external pump supplies E.KO IONISER® 2

Car wash

Requirement:

Residues and streaks on the cars after final cleaning. Frequent legionella formation in the water circuit.

Solution:

Installation of an EASYRO® water treatment system with additional dosing station for henndrixx® disinfectant.

1. Dosing henndrixx® disinfectant into the circulation water prevents legionella formation.

2. Osmosis water for refilling the water circuit prevents salinisation and saves a lot of detergent.

3. The purest osmosis water in the final rinse water for final cleaning provides stain-free results.

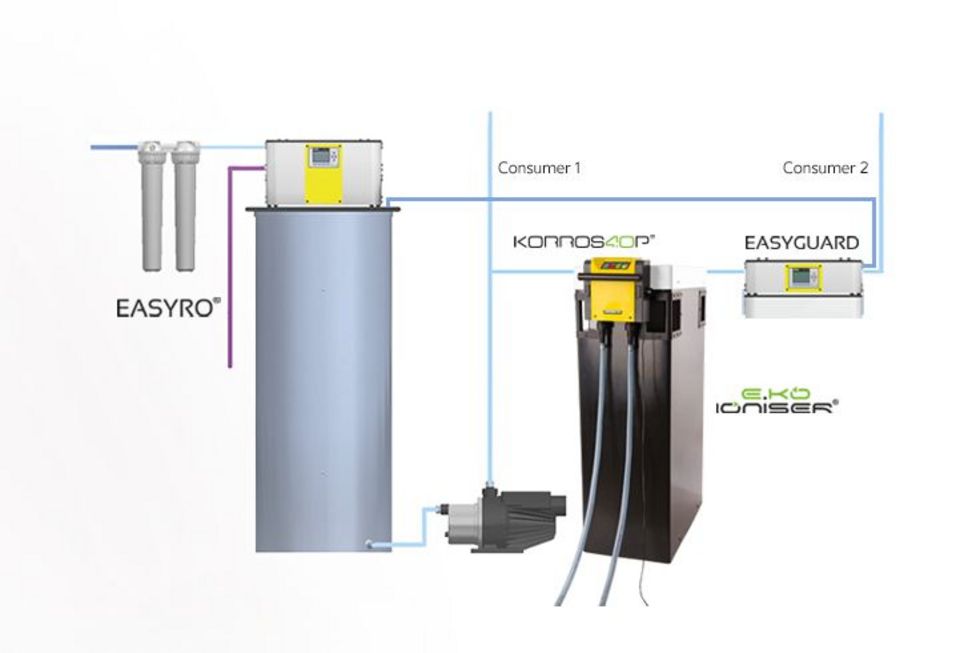

Supply for complete production process

Requirement:

Different water qualities are needed for different work areas.

Consumer 1 - Eroding department refill and other departments

Consumer 2 - Washing machines and coffee machines

Solution:

Installation of an EASYRO® water treatment system with subsequent smoothing by the E.KO IONISER® 1503 incl. EASYGUARD for monitoring. If a purity of < 1µs/cm has not been achieved, the water goes through the smoothing process again.

Consumer 1: Osmosis water

Consumer 2: Ultrapure water - conductance of 0.055-0.1 µs/cm, constant neutral pH, also removes carbonic acid and silicic acid

Removal of Total Organic Carbon (TOC) of < 1 ppb, resistance of > 18.2 MΩ (at 25°C).

EDM - Electrical Discharge Machining

Requirement:

Full logistics handling for the exchange of used E.KO IONISER® for new ones via the dealer.

Solution:

A trader dashboard has been set up. All E.KO IONISERs® were connected to the dealer dashboard by means of their KORROSTOP4.0® measuring devices.

The dealer receives the status message from the customer's connected E.KO IONISER® via each KORROSTOP4.0® and organises the exchange of used for new in good time.

The customer is thus guaranteed a continuous, qualitative process water supply.

Service and drinking water for single-family house

Requirement:

Supply of a single-family house with service and drinking water. No use of local water possible in this location. Water treatment of a well contaminated by agricultural use with severe microbial contamination.

Contaminated pipe network (many dead pipes) throughout the house.

Solution:

Flushing of the complete pipe network with henndrixx® disinfectant. The pipe network is flushed every 6 months during system maintenance to prevent the formation of germs in the dead pipes.

Installation of an EASYRO® water treatment system with coordinated pre-filter stages including a certified flow-through UVC system. This prevents the penetration of bacteria, viruses or germs and makes the water fit for consumption.