EASYRO® water treatment systems have been specially developed for industry and production processes and produce the purest, residue-free process water reliably, cost-effectively and in an environmentally friendly manner.

Water treatment based on reverse osmosis.

2 separate outlets for different water qualities.

Output 1 - conductance adjustable

Output 2 - conductance fixed

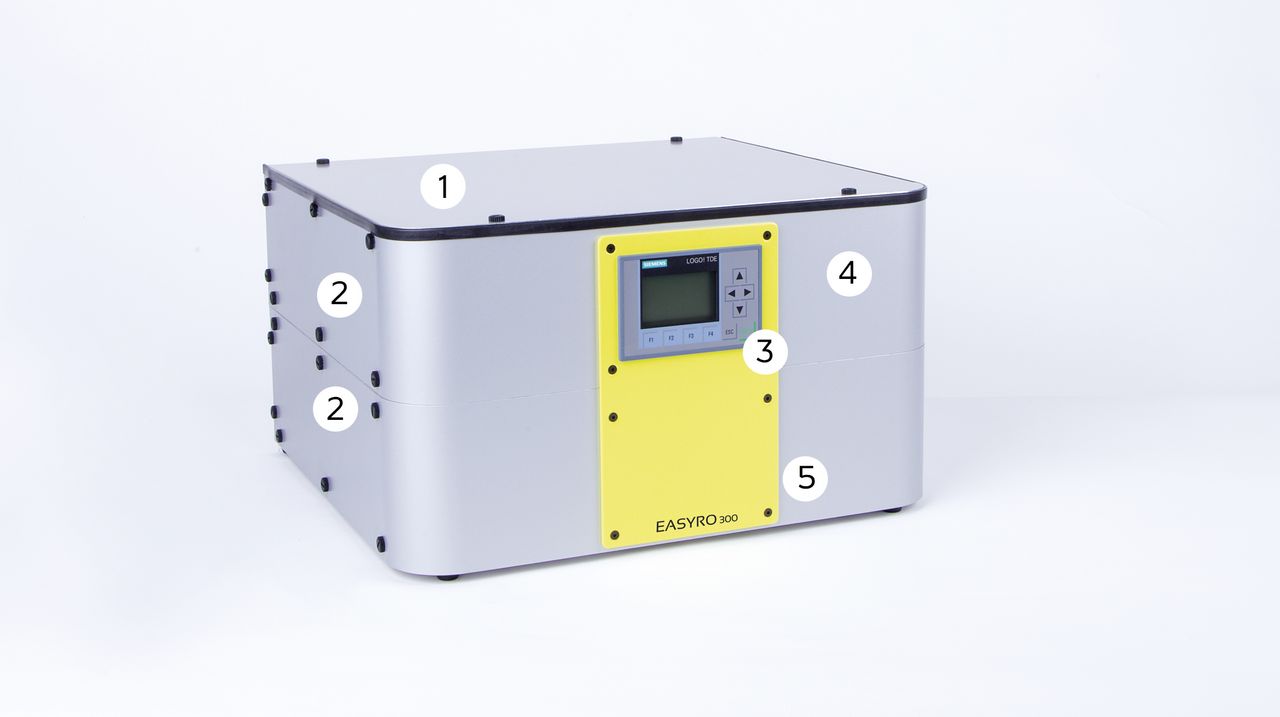

Modular construction - expansion possible at any time.

Standard feature for pure water output

If the actually produced conductance of the permeate is above the set value, it is discarded until the desired, set conductance is reached again.

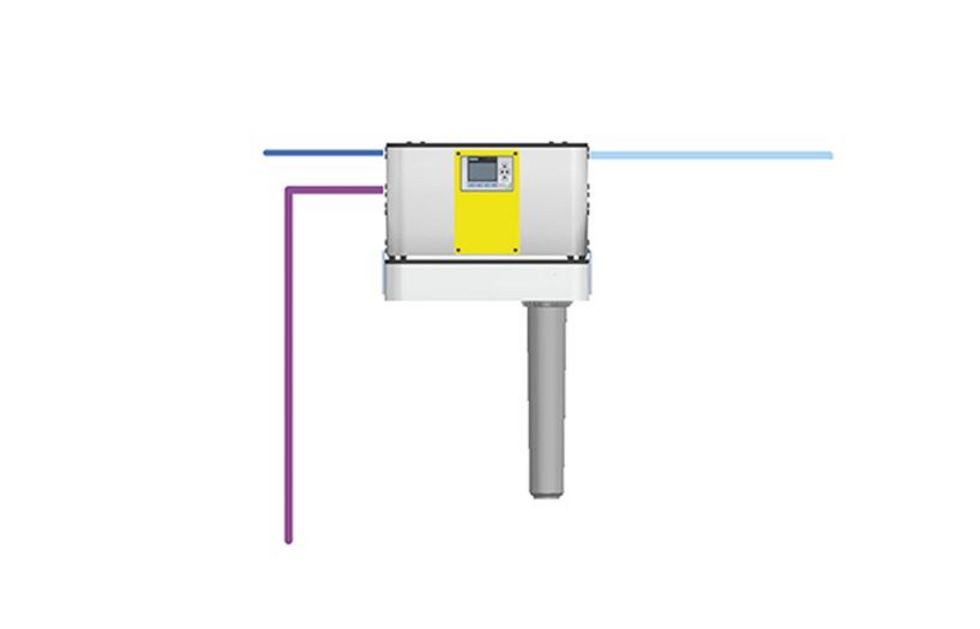

Inlet ¾“ OT inlet valve with dirt trap

Connection for Level probe

* only for level-controlled systems in conjunction with a storage tank

Outlet 10 mm or DN 20

For setting the conductance for water output 1

250-600 W depending on EASYRO model

(See technical data for power consumption)

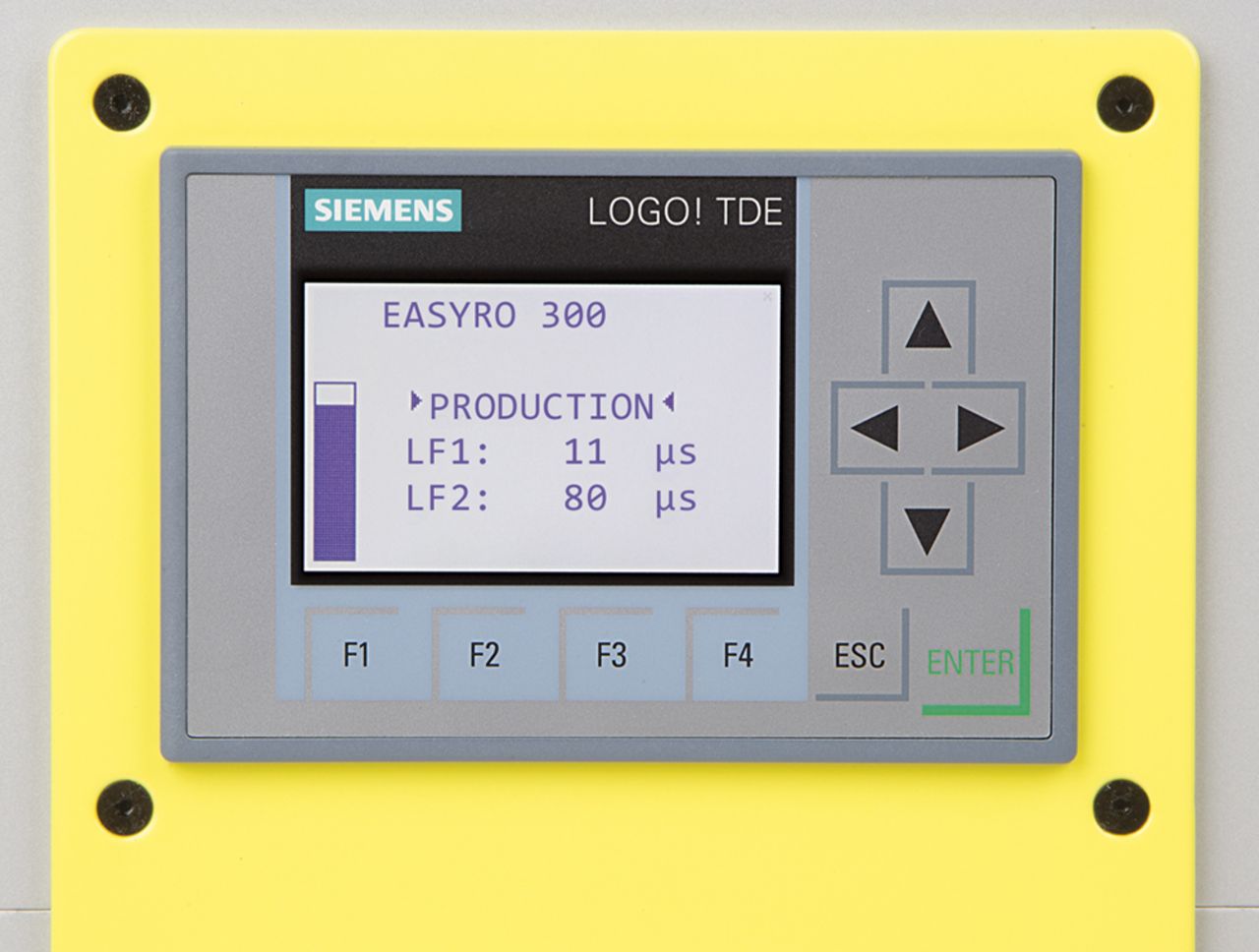

Password-protected programming of operating parameters.

Operator function via password at different levels

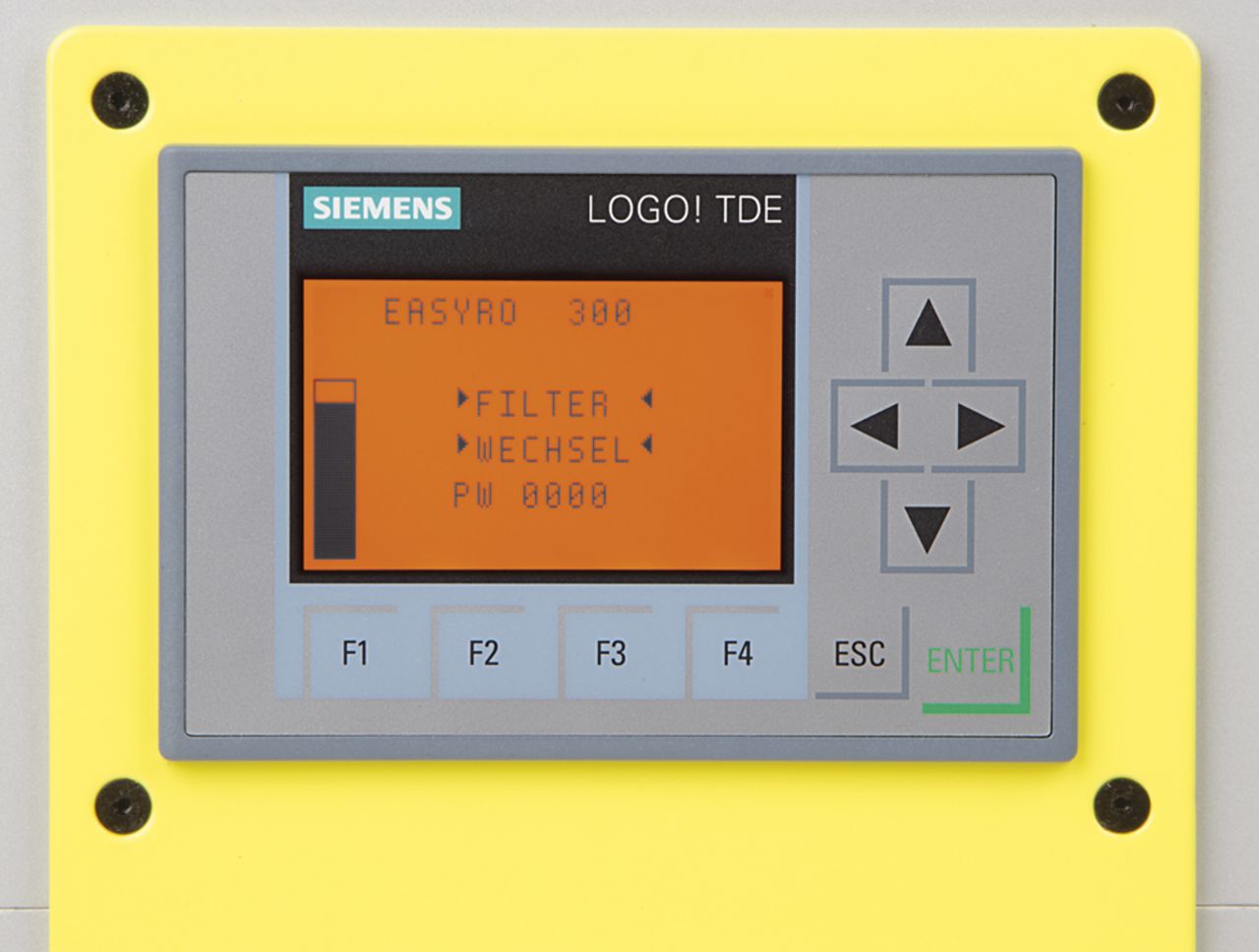

Warnings and information such as discard mode, filter change, membrane check, etc. are displayed with orange backlighting.

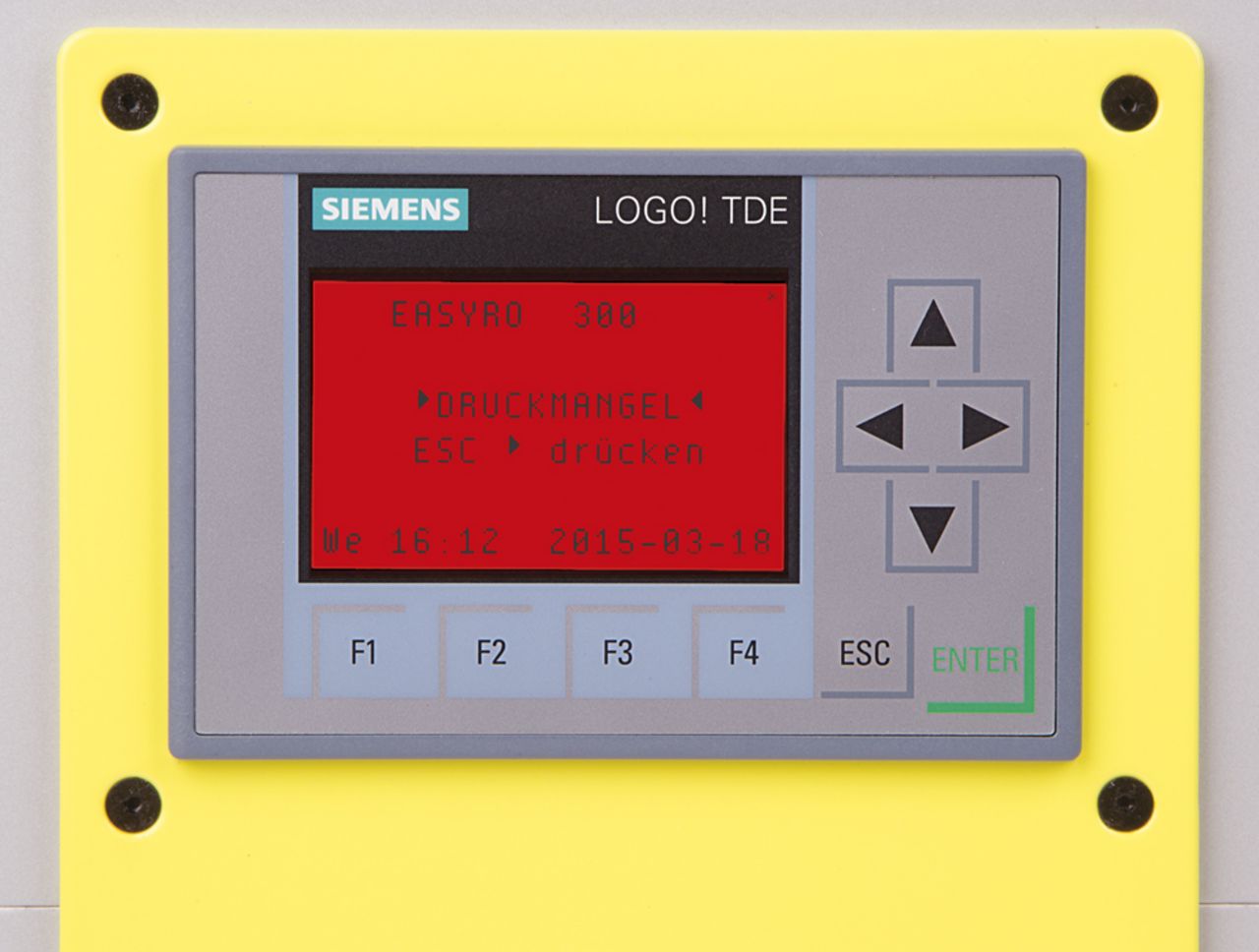

The optical alarm messages highlighted in red allow for an immediate response to errors in the process flow. This includes lack of pressure, motor temperature, level probe check, leaks, etc.

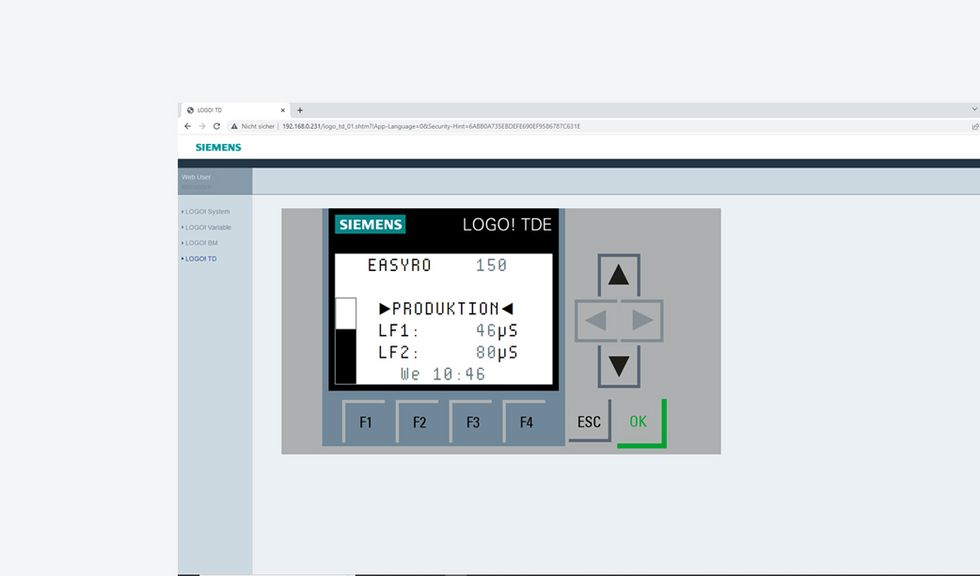

Simple handling and real-time communication via Ethernet characterize the Siemens LOGO! 8.

The integrated Web Server enables the monitoring and control via Wi-Fi* and via Internet. Of course, this is password protected and compatible with all popular browsers. The LOGO! 8 can be operated via PC, smartphone or tablet.

SMS communication** for alerting and remote control via mobile phone.

* Wi-Fi module required

** GSM module required

We install tubular low-pressure high-performance membranes in all our EASYRO® reverse osmosis systems.

The membrane technology used here is state-of-the-art.

Only industrial components are used, which are in no way comparable with conventional household membranes.

| Power consumption | 250 W |

| Voltage | 230 V AC/50 Hz |

| Noise level | > 60 dB(A) |

| Fusing | 10 A |

| Minimum flow | 10 l/min |

| Input pressure | 2-6 bar |

| Device connection | 3/4" OT |

| Wastewater connection | JG 10/DN 20 |

| Pump outlet | 1" OT |

| Output (24 hr)* | 2400 l |

| Output pressure outlet 1 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Output pressure outlet 2 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Overpressure alarm | incl. |

* Depending on raw water quality and temperature

| Desalination rate min. | 95 % |

| Desalination rate max. in combination with polisher** | 99,99 % |

| Wastewater*** min. | 35 % |

| Outlets | 2 x JG 10 |

| Outlet 1 | Adjustable (measuring range 2-400 µs/cm) |

| Outlet 2 | Pure water fixed |

| Weight, empty | approx. 18 kg |

| Dimensions (L/W/H) | 450/490/147 mm |

** up to 0,01 µs/cm

*** Depending on raw water quality and membrane service life

| Power consumption | 250 W |

| Voltage | 230 V AC/50 Hz |

| Noise level | > 60 dB(A) |

| Fusing | 12 A |

| Minimum flow | 15 l/min |

| Input pressure | 2-6 bar |

| Device connection | 3/4" OT |

| Wastewater connection | JG 10/DN 20 |

| Pump outlet | 1" OT |

| Output (24 hr)* | 4800 l |

| Output pressure outlet 1 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Output pressure outlet 2 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Overpressure alarm | incl. |

* Depending on raw water quality and temperature

| Desalination rate min. | 95 % |

| Desalination rate max. in combination with polisher** | 99,99 % |

| Wastewater*** min. | 35 % |

| Outlets | 2 x JG 10 |

| Outlet 1 | Adjustable (measuring range 2-400 µs/cm) |

| Outlet 2 | Pure water fixed |

| Weight, empty | approx. 25 kg |

| Dimensions (L/W/H) | 450/490/284 mm |

** up to 0,01 µs/cm

*** Depending on raw water quality and membrane service life

| Power consumption | 600 W |

| Voltage | 230 V AC/50 Hz |

| Noise level | > 60 dB(A) |

| Fusing | 16 A |

| Minimum flow | 20 l/min |

| Input pressure | 2-6 bar |

| Device connection | 3/4" OT |

| Wastewater connection | JG 10/DN 20 |

| Pump outlet | 1" OT |

| Output (24 hr)* | 9600 l |

| Output pressure outlet 1 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Output pressure outlet 2 | adjustable 0.4-6.5 bar (factory-set 4 bar) |

| Overpressure alarm | incl. |

* Depending on raw water quality and temperature

| Desalination rate min. | 95 % |

| Desalination rate max. in combination with polisher** | 99,99 % |

| Wastewater*** min. | 35 % |

| Outlets | 2 x JG 10 |

| Outlet 1 | Adjustable (measuring range 2-400 µs/cm) |

| Outlet 2 | Pure water fixed |

| Weight, empty | approx. 50 kg |

| Dimensions (L/W/H) | 450/490/558 mm |

** up to 0,01 µs/cm

*** Depending on raw water quality and membrane service life

Do you have any questions? Contact us, we will be happy to advise you.

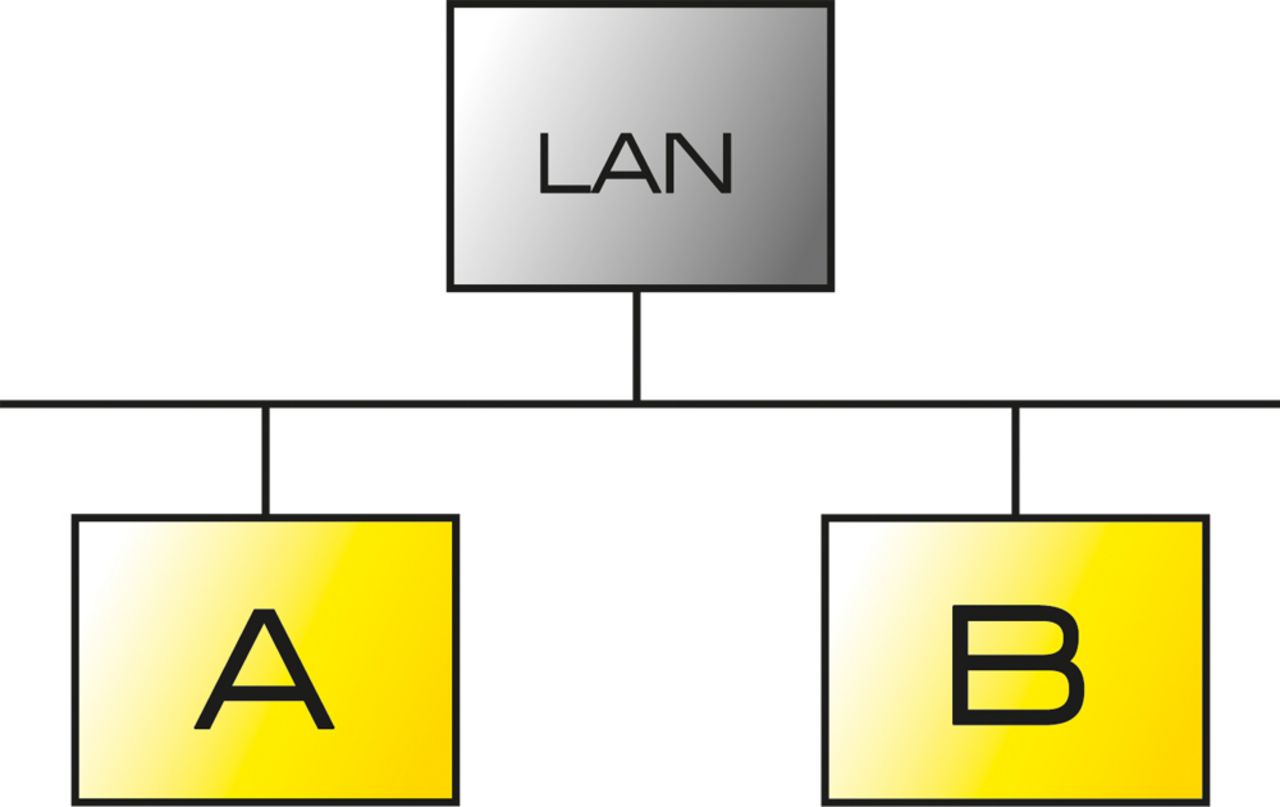

The redundancy principle is the most common approach to improving performance and preventing the failure of important components. These additional resources provide:

increased fail safety = reliability or reduction in the probability of failure of

components that are important for production.

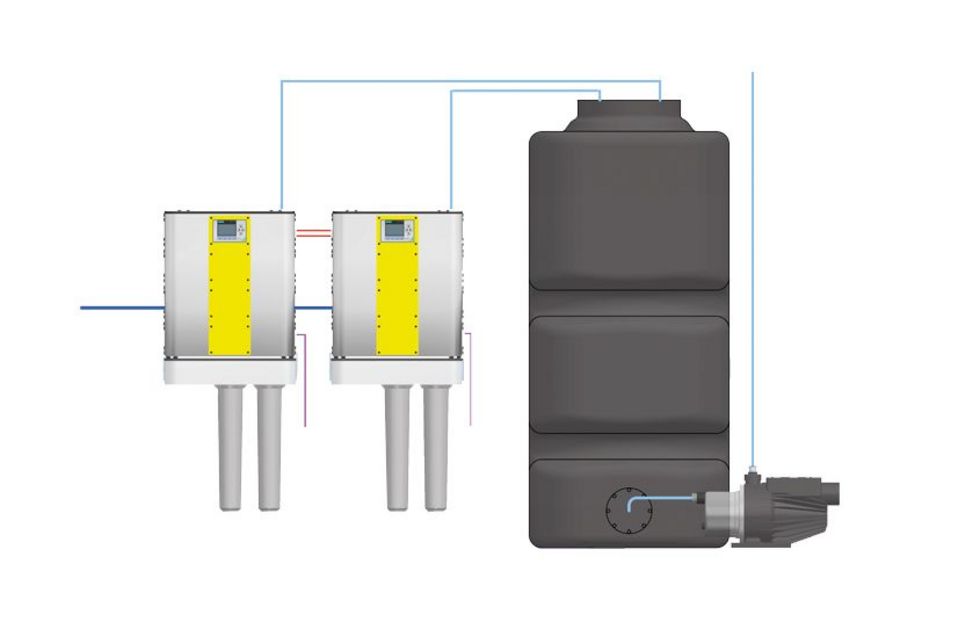

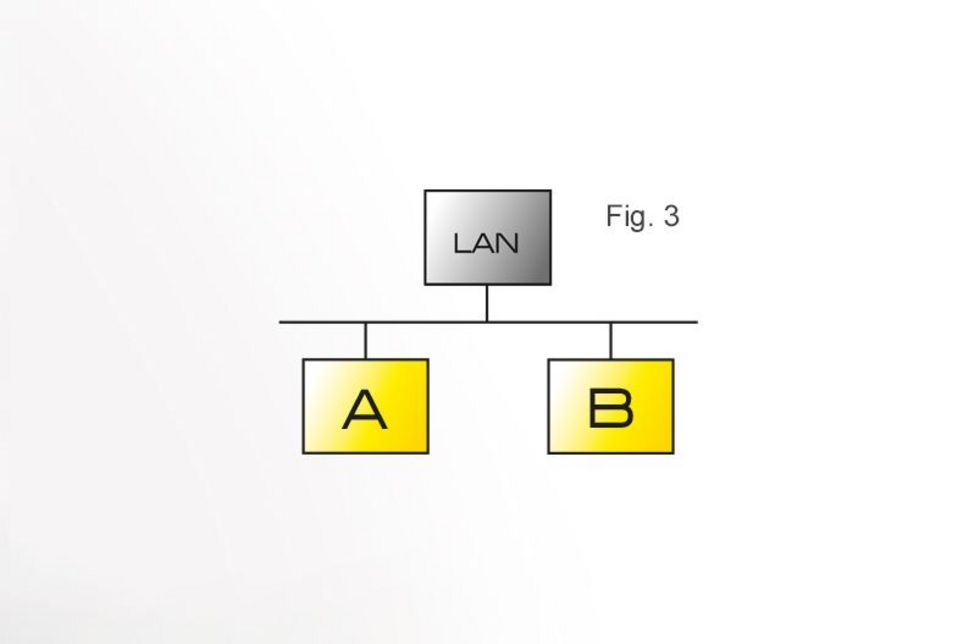

The system consists of 2 functioning units (master+slave). One unit is designated as the master and takes over the main control.

The two water treatment units are connected to each other via the ETHERNET (Master/Slave Connector) located on the back of the unit.

Picture on the right: 2 x EASYRO® 600 in redundant operation

The following variants of the redundancy design are possible:

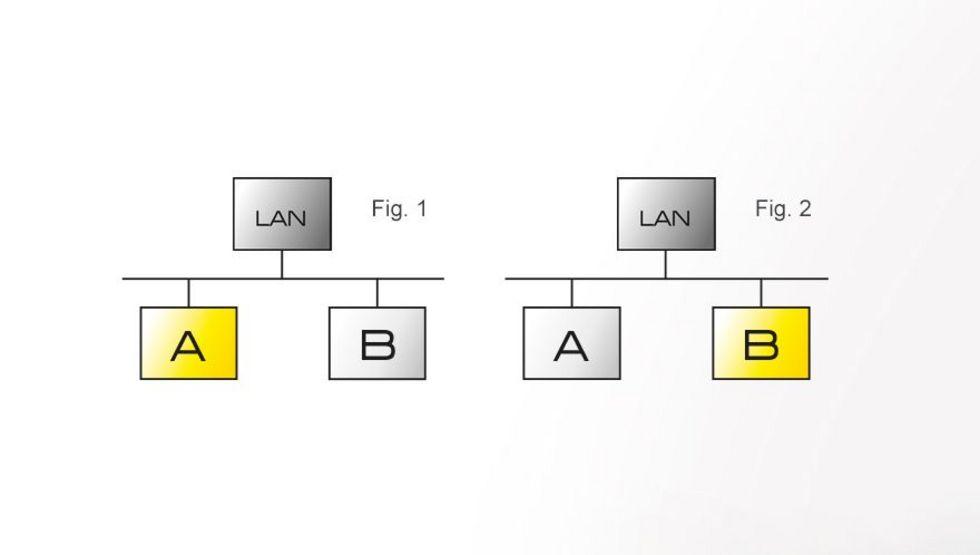

Alternately, only one system is active at a time.

Fig. 1

The master (system A) is working. The slave (system B) is in "Stand by" mode waiting for its signal.

Fig. 2

The master passes the signal to the slave. The slave (system B) starts to work. While the slave works (system A), the master is now in the "Stand by" mode.

The pendulum system offers a bonus feature to be able to cover possible withdrawal peaks.

Fig. 3

While in dual mode, both units (A + B) work simultaneously as one unit. This means twice the power is

available to you.

The quality of your raw water and the desired degree of purity of the process water after treatment are decisive for the choice of suitable pre-filters and for the possible combinations of reverse osmosis and deionisation.

Should you require accessories outside of our product range, we will be happy to help.

Contact us, we will be happy to advise you.

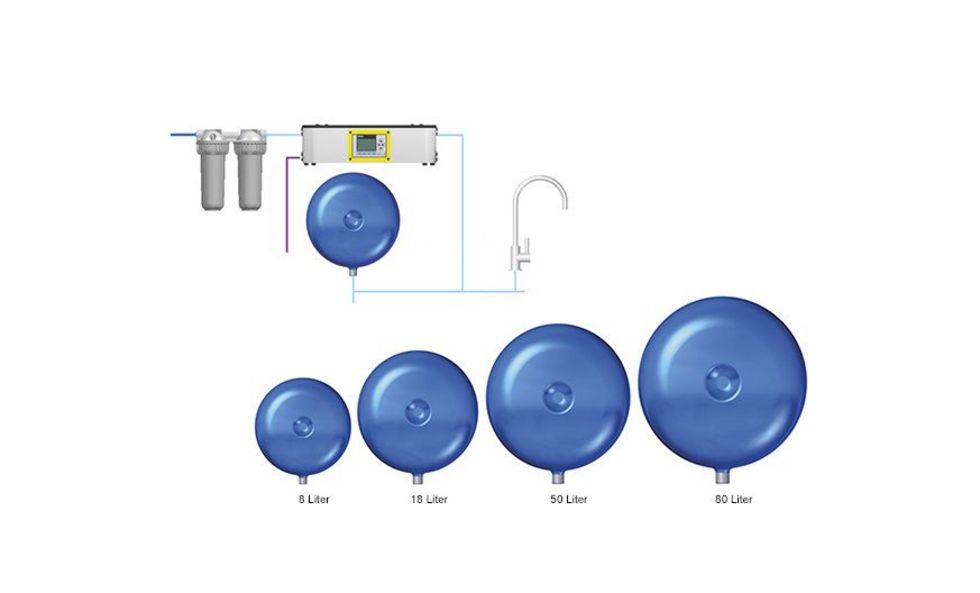

With the appropriate accessories, you can use the EASYRO® units for individual or central supply.

Depending on whether you prefer an unpressurised system with a reserve tank, want to feed directly into your ring main or want a pressure-controlled water treatment system in combination with a membrane tank - we offer the optimal solution for your needs.

For small and very small quantities of treated water, we recommend one of our membrane tanks from 8 to 80 litres nominal volume.

These pressurised tanks are particularly suitable in laboratories for feeding the rinsers.

EASYRO® water treatment systems are mounted on the wall in the base cabinet to save space.

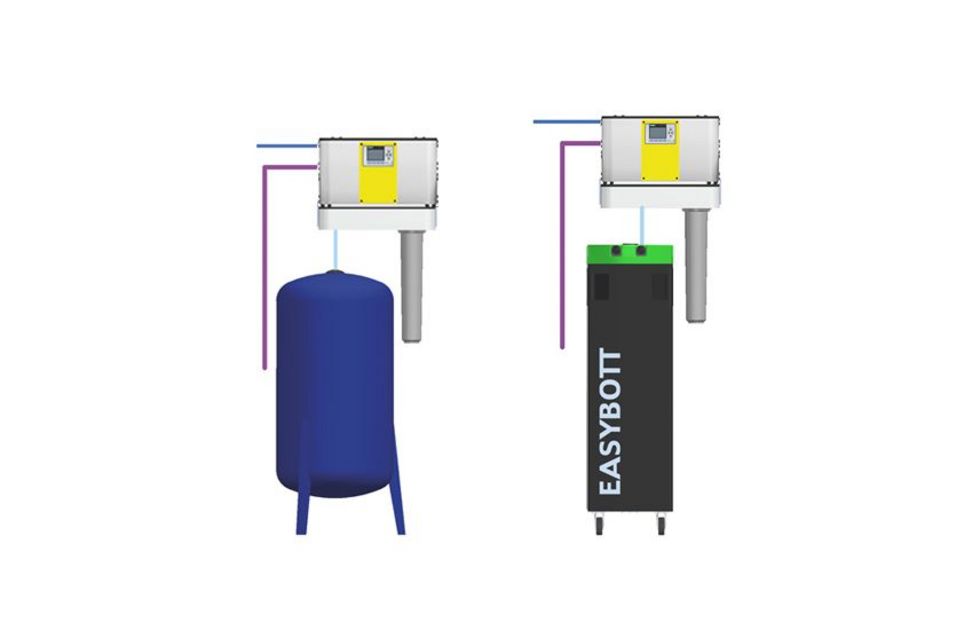

Reserve tanks with larger volumes are available in different materials and sizes.

Depending on the application, a plastic HD-PE tank or a stainless-steel tank (water-carrying parts made of stainless steel) is advantageous.

All tanks can be used as a basic tank and as an additional tank, and can thus be connected to each other*.

This is a simple, cost-effective way to create large water reserves.

* only equal tank sizes

Contact us, we will be happy to advise you.

Pressurised tanks with pedestals are available with a nominal volume of 200 or 300 litres.

They have pressure expansion vessels with fixed gas filling with a max. permissible pressure of 16 bar.

The EASYBOTT refill trolley offers a mobile pressurised tank variant.

Contact us, we will be happy to advise you.

The optimal treatment of the water is of great importance for the preparation of cooling lubricants. Using pure water as a preparation medium for cooling lubricants extends the service life of the emulsion and reduces the overall process costs through increased operational reliability.

Learn more

Whether for individual cleaning processes, washing systems for cleaning production parts, ultrapure water for highly sensitive production processes or ultra-fine cleaning, our EASYRO® series offers optimum water quality for the highest demands.

Learn more

Our EASYRO® series in combination with our E.KO IONISER® 1503 for subsequent smoothing guarantees the highest purity of fresh water and thus trouble-free operation of your system.

Learn more

Type 1 ultrapure water is essential for precisely reproducible analysis results. Our EASYRO® series in combination with our E.KO IONISER® 1503 for subsequent smoothing fulfils even the high requirements in ultra-fine cleaning and medical technology.

Learn more

Whether as an ingredient, for processing or for cleaning and hygiene, the purest water plays an important role in food production. With the EASYRO® reverse osmosis system you can produce the purest water for your applications in a space-saving, cost-effective way.

Learn more

Our EASYRO reverse osmosis systems free your fresh water from all disturbing substances and produce the purest water for your cleaning process.

Learn more

In the EDM sector, the EASYRO® series offers a refill system with optimally treated water. The EASYRO® provides constant, pH-stable water quality and thus prevents conductance variations during the refilling process.

Learn more